Documentation

The aim of this validation is to compare the simulation results performed in SimScale using the proprietary solver, Multi-purpose, with the experimental data published by SVA Potsdam under the study Potsdam Propeller Test Case (PPTC)\(^1\).

The objective is to test the Multi-purpose solver’s ability to compute the thrust, torque, and propeller efficiency under open water test conditions.

The Propeller model VP1304 can be downloaded from the SVA PPTC smp’11 Workshop. For simulation purposes in SimScale, an external flow volume is created around the propeller to replicate a propeller immersed under water. The original Propeller VP1304 as mentioned in the SVA report\(^1\) is as shown in Figure 1:

And the schematic is as follows:

The propeller diameter is 0.25 \(m\), shaft diameter is 0.05 \(m\). The propeller blades are placed 0.57 \(m\) from the inlet.

The CAD model used for validation purposes in SimScale is as follows:

Important

Although the report performs cavitation tests as well, this validation case only compares its results for the thrust, torque and efficiency . Cavitation scenarios are not covered.

Analysis Type: Steady-state, Multi-purpose with k-epsilon turbulence model.

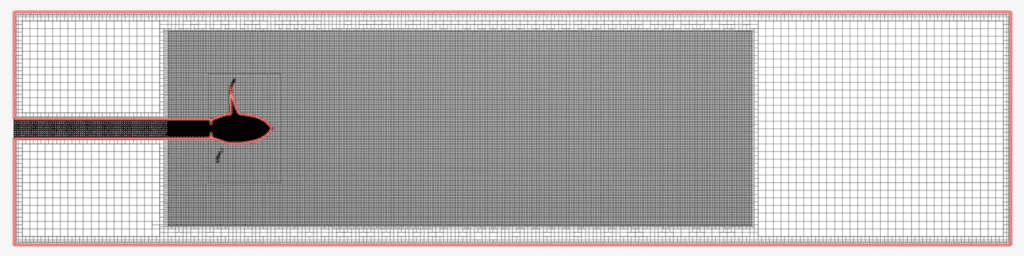

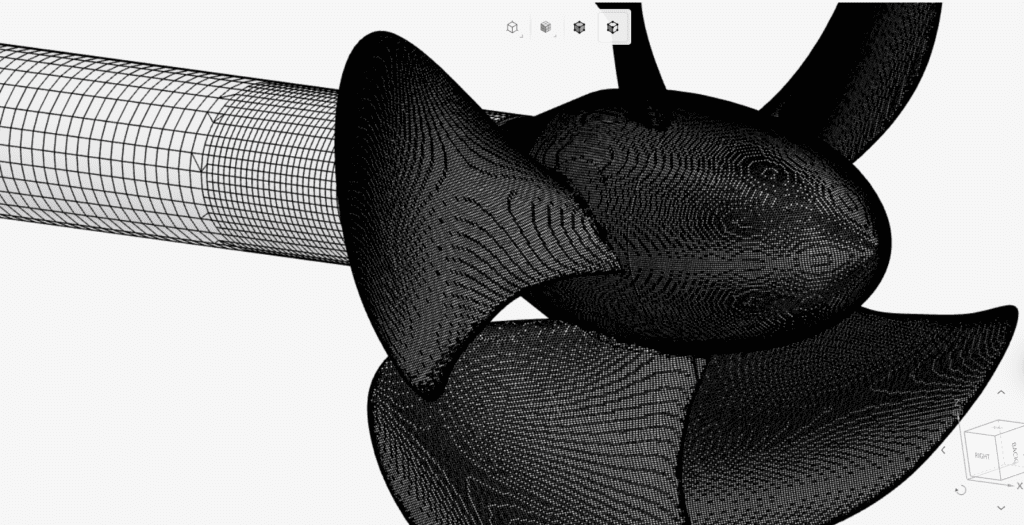

Mesh and Element Types:

The mesh was created with SimScale’s Multi-purpose mesh type, which is a body-fitted structured mesh. An automatic sizing definition was defined with two additional region refinements for the wake region and around the rotating region, as well as one surface refinement to capture the blade profiles accurately.

| Mesh Type | Fineness | Target Cell Size (surface refinement for rotor) \([m]\) | Target Cell Size (region refinement for wake) \([m]\) | Target Cell Size (region refinement for rotating zone) \([m]\) | Number of cells | Element Type |

| Automatic with region refinements | 7 | 1e-3 | 5e-3 | 4e-3 | 22210996 | 3D Hexahedral |

The resulting mesh is captured in Figures 4 and 5. Figure 4 shows cell distribution on a mid-plane while Figure 5 shows a closeup view of the surface refinements applied on the rotor.

Fluid:

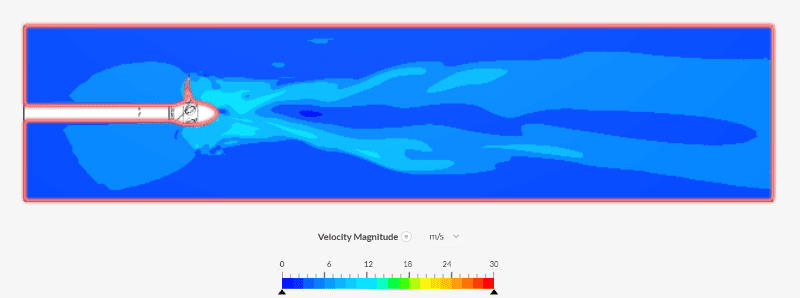

Figure 4 shows the schematic of the boundary conditions applied:

A total of 11 inlet velocities were tested for the same angular velocity.

| Boundary Condition | Value |

| Velocity inlet \([m/s]\) | 1.762 2.17 2.594 2.995 3.418 3.89 4.359 4.725 5.207 5.603 5.903 |

| Pressure outlet \([Pa]\) | 0 (Guage static pressure) |

| Symmetry | – |

| Rotating zone (MRF) | 94.25 \(rad/s\) angular velocity (15 revolutions per second) in the negative x-axis |

The result output for thrust and torque exerted by the propeller and the propeller efficiency obtained from the SimScale simulation are compared with the experimental measurements reported in the SVA study\(^1\).

Thrust values exerted by the propeller VP1304 for the 11 input velocities were obtained by adding the pressure and viscous forces acting on the rotor (hub + blades) in the x direction.

For thrust \((T)\), the thrust coefficient is calculated as:

$$K_T = \frac{T}{\rho \times n^2 \times D^4} \tag{1}$$

A quantity called Advance coefficient is used for comparison, which is given by

$$J = \frac{v}{n \times D}$$

Where

| Velocity \([m/s]\) | Advance Coefficient | Thrust, Simscale \([N]\) | Thrust Coefficient, SimScale | Thrust Coefficient, SVA | Error % |

| 1.762 | 0.469867 | 516.5 | 0.5890 | 0.6791 | -13.274 |

| 2.17 | 0.578666 | 486 | 0.5542 | 0.6187 | -10.427 |

| 2.594 | 0.691733 | 425 | 0.4846 | 0.5562 | -12.869 |

| 2.995 | 0.798666 | 407.07 | 0.4642 | 0.4895 | -5.1809 |

| 3.418 | 0.911466 | 378.845 | 0.4320 | 0.4312 | 0.18104 |

| 3.89 | 1.03733 | 314.75 | 0.3589 | 0.3645 | -1.5485 |

| 4.359 | 1.1624 | 255.21 | 0.2910 | 0.3020 | -3.6561 |

| 4.725 | 1.26 | 207.52 | 0.2366 | 0.2437 | -2.9113 |

| 5.207 | 1.38853 | 143.3 | 0.1634 | 0.175 | -6.6184 |

| 5.603 | 1.49413 | 81.43 | 0.0928 | 0.1166 | -20.404 |

| 5.903 | 1.57413 | 29.78 | 0.0339 | 0.0583 | -41.781 |

Torque values exerted by the propeller VP1304 for the 11 input velocities were obtained by calculating total moments (sum of pressure and viscous moments) acting on the rotor (hub + blades) in the x-direction.

For torque \((Q)\), the thrust coefficient is calculated as:

$$K_Q = \frac{Q}{\rho \times n^2 \times D^5} \tag{2}$$

| Velocity \([m/s]\) | Advance Coefficient | Torque, Simscale \([Nm]\) | Torque Coefficient, SimScale | Torque Coefficient, SVA | Error % |

| 1.762 | 0.469867 | 35.94 | 0.1639 | 0.1620 | 1.1469 |

| 2.17 | 0.578666 | 34.2 | 0.1560 | 0.1481 | 5.3200 |

| 2.594 | 0.691733 | 31.5 | 0.1436 | 0.1352 | 6.2723 |

| 2.995 | 0.798666 | 29.415 | 0.1341 | 0.1220 | 9.9070 |

| 3.418 | 0.911466 | 29.44 | 0.1342 | 0.1102 | 21.853 |

| 3.89 | 1.03733 | 27.375 | 0.1248 | 0.0966 | 29.178 |

| 4.359 | 1.1624 | 23.6 | 0.1076 | 0.0835 | 28.861 |

| 4.725 | 1.26 | 22.4 | 0.1021 | 0.0716 | 42.575 |

| 5.207 | 1.38853 | 17.535 | 0.0799 | 0.0577 | 38.605 |

| 5.603 | 1.49413 | 14.65 | 0.0668 | 0.0445 | 49.891 |

| 5.903 | 1.57413 | 11.975 | 0.0546 | 0.0331 | 64.904 |

Propeller efficiency\((\eta)\) for the 11 input velocities was obtained using equation 3:

$$ \eta = \frac{K_T}{K_Q} \times \frac{J}{2 \pi} \tag{3}$$

| Velocity \([m/s]\) | Advance Coefficient | Efficiency, SimScale | Efficiency, SVA | Error % |

| 1.762 | 0.469867 | 0.2686 | 0.3145 | -14.593 |

| 2.17 | 0.578666 | 0.3271 | 0.3854 | -15.107 |

| 2.594 | 0.691733 | 0.3713 | 0.45 | -17.478 |

| 2.995 | 0.798666 | 0.4397 | 0.525 | -16.234 |

| 3.418 | 0.911466 | 0.4666 | 0.575 | -18.837 |

| 3.89 | 1.03733 | 0.4745 | 0.6333 | -25.069 |

| 4.359 | 1.1624 | 0.5001 | 0.6770 | -26.131 |

| 4.725 | 1.26 | 0.4644 | 0.6895 | -32.647 |

| 5.207 | 1.38853 | 0.4514 | 0.6979 | -35.307 |

| 5.603 | 1.49413 | 0.3304 | 0.6312 | -47.652 |

| 5.903 | 1.57413 | 0.1557 | 0.475 | -67.208 |

References

Note

If you still encounter problems validating your simulation, then please post the issue on our forum or contact us.

Last updated: December 4th, 2025

We appreciate and value your feedback.

Sign up for SimScale

and start simulating now